Materials

Olsberg produces cast iron with lamellar graphite according to DIN EN 1561 and cast iron with nodular graphite according to DIN EN 1563.

The following materials are manufactured:

Cast iron with lamellar graphite

Gray cast iron: unrecognized all-rounder with innovation potential

| Material according to DIN EN 1561 | Material according to DIN EN 1691 (old designations) | ||

|---|---|---|---|

| Abbreviation | Number | Abbreviation | Number |

| EN-GJL-150 | EN-JL 1020 | GG-15 | 0.6015 |

| EN-GJL-200 | EN-JL 1030 | GG-20 | 0.6020 |

| EN-GJL-250 | EN-JL 1040 | GG-25 | 0.6025 |

| EN-GJL-300 | EN-JL 1050 | GG-30 | 0.6030 |

The Königshütte plant produces only EN-GJL-150 and EN-GJL-200 materials.

In Germany, the share of gray iron in total foundry production has remained relatively constant at around 60 percent for years. The majority of this goes to the automotive and mechanical engineering sectors. This may come as a surprise to some: The material has not only proven itself millions of times over under some of the toughest operating conditions, but also stands for filigree design and weight savings.

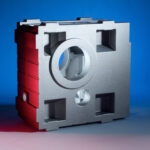

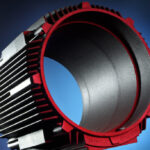

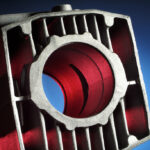

Common gray iron castings include electric motor rib housings, gearbox housings, compressor and pump housings, valves and fittings, and furnace parts. In these areas of application, the material is practically non-substitutable in terms of both material properties and economy. On the contrary, gray cast iron is a "modern classic". State-of-the-art molding, casting and machining processes contribute to its preference in many applications over other materials such as cast steel, malleable cast iron or cast aluminum, not least for cost reasons.

Convincing alternatives not in sight?

Take aluminum, for example: This material has a significantly lower density, which is expected to offer weight advantages in various areas of application. However, the tensile strength of aluminum is much lower than that of cast iron. To achieve the same stability, aluminum parts must therefore be dimensioned more voluminously than a comparable gray cast iron part, which reduces the actual weight advantage. Since aluminum cannot be subjected to such high mechanical stresses, steel bearing bushes, for example, have to be pressed in, which leads to a further increase in weight.

Winner in cutthroat competitionv

In contrast, gray cast iron can be used to cast much more filigree, extremely resilient parts, which also has functional advantages in many areas of application. In other words, "lightweight construction" is also possible with gray cast iron - not as a result of low density, but due to optimized, load-optimized designs. It also has a significantly better energy and waste balance in the manufacturing process. Gray cast iron, for example, is fully recyclable. In the pump and electric motor sectors, but also in other industries, there is currently even a return to gray cast iron as a material with higher load-bearing capacity, which is technically less problematic and more economical.

Cast iron with nodular graphite

High load-bearing capacity and versatile use - ductile cast iron: material with a future

| Material according to DIN EN 1563 | Material according to DIN EN 1693-1 or DIN 1693-2 (old designations) |

||

|---|---|---|---|

| Abbreviation | Number | Abbreviation | Number |

| EN-GJS-400-18U-LT | EN-JS 1049 | GGG-40.3 | 0.7043 |

| EN-GJS-400-18U-RT | EN-JS 1059 | - | - |

| EN-GJS-400-18U | EN-JS 1062 | - | - |

| EN-GJS-400-15U | EN-JS 1072 | GGG-40 | 0.7040 |

| EN-GJS-500-7U | EN-JS 1082 | GGG-50 | 0.7050 |

| EN-GJS-600-3U | EN-JS 1092 | GGG-60 | 0.7060 |

| EN-GJS-700-2U | EN-JS 1102 | GGG-70 | 0.7070 |

Spheroidal graphite cast iron is produced exclusively in our Olsberg plant.

With an excellent price/performance ratio, favorable service properties and a wide range of applications, ductile cast iron - also known as nodular cast iron - has become the rising star among casting materials. Since the mid-1980s, its share of total castings production in Germany has grown from just under 23 percent to around one third. In 1995, the threshold of one million tons per year was exceeded for the first time.

Its properties are increasingly opening up industrial areas to this material, where previously only other materials such as steel were used. Compared to gray cast iron, ductile cast iron offers outstanding possibilities for weight-optimized design of castings.Compared to gray cast iron, ductile cast iron offers outstanding possibilities for weight-optimized design of castings. Among other things, it is possible to cast much thinner walls, while the castings are significantly more robust and less sensitive to mechanical stress due to their higher ductility. Added to this is good machinability. The use of ductile iron is increasingly replacing cast steel, as well as forgings and welded structures.

The reliable production of assured ductile iron grades requires not only a high level of metallurgical know-how but also a well-established and properly functioning quality assurance system.

Particular importance is also attached to my close and trusting cooperation between the casting customer and the foundry - especially in the optimization of castings with the aim of minimizing material usage and significantly reducing weight. In addition, against the background of the increasing trend towards "single sourcing", efficient suppliers who can offer their customers a wide range of products from a single source are also in demand in the ductile iron sector